Our main products are chain , gears, sprocket, Needle Roller bearings, Cylindrical Roller Bearings, Rod end Bearings, Spherical plain bearings, Track roller Bearings for Guideway, Roller Bearings, Combine Bearings for forklifts, Water Pump Bearings, SNR Auto Bearings and all kinds of Spherical Bearings.

Overview

Quick Details

- Condition:

-

New

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant, OEM

- After Warranty Service:

-

Online support

- Local Service Location:

-

none, United States

- Showroom Location:

-

none

- Type:

-

Bearing

- Use:

-

Cultivators

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- coThe computer then compares the output subassembly stack height to the distance between the housing bearing seats and calculates the shim pack required for the desired bearing endplay. Using the worm-gear centerline measurement, it shows assemblers how to distribute shims between the front and rear bearings to precisely center the gear in the housing. Measurement accuracy is ±0.001 in. Total cycle time, excluding loading and unloading, is less than 20 sec.ndition:

-

new

- Suitable:

-

1-50 ton excavator,crane ,skid steer loader

- auger diameter:

-

75-1500mm

- Depth:

-

20M

- STD oil flow:

-

75L/M

–Driven (outer) yoke same as drive yoke but is mounted on the implement. There are two types of shafts, domestic and metric, which are identifiable by their shapes. Domestic are generally one of four shapes: round, square, rectangle or splined. Metric are: bell, star or football shaped. In either case the primary (front) shaft is the same shape as the secondary shaft, only bigger so that the secondary shaft fits inside. This allows a telescoping effect to take place when the implement is raised on the 3 pt. or during a turning movement such as a bailer. All shafts have to be sized before use. Attach the implement to the 3 pt. and raise and support it. Attach the proper end to the tractor and attempt to attach the other to the implement. If the shaft is too long trim one of the shafts with a hack saw and try it again until it fits. This allows for the implement to be raised without binding. The shafts should overlap as much as allowed.

- STD pressure:

-

170 bar

- outshaft:

-

41/51HEX, 65 Rnd,75Squ

- Color:

-

blue or black

- Item:

-

drill dirt auger bit

Supply Ability

- Supply Ability:

- 1000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- BOX

- Port

- QINGDAO,DALIAN, SHANGHAI, NINGBO

Online Customization

hydraulic auger drill drive for mini piling machine Torque by excavator

Product Description

Earth Drills are renowned throughout the world for being the best augur system available. A large range of models are available to suit any machine and hole boring task from the smallest fencing job through to major piling works. With a revolutionary gearbox and non-dislodgement shaft, the EPG Earth Drill is built to out-perform and outlast, turning your machine into a truly universal piece of equipment.

Why we choose this earth auger?

It is obviously that earth auger is more efficient than manual work. Besides, using our product is safer than manual work. The hole which dig by the earth auger is more beautiful than man did.

Features & Benefits

– Non-dislodgment shaft.

– Epicyclic Gearbox

– Hose & Coupler options

– High quality hydraulic motor

– Forged hood ears

– Shock-lock tooth locking system

– Augers from 75mm to 1200mm

– new earth drills

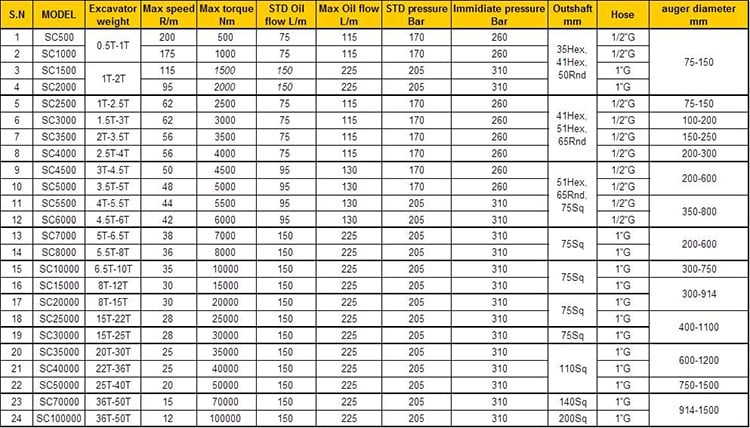

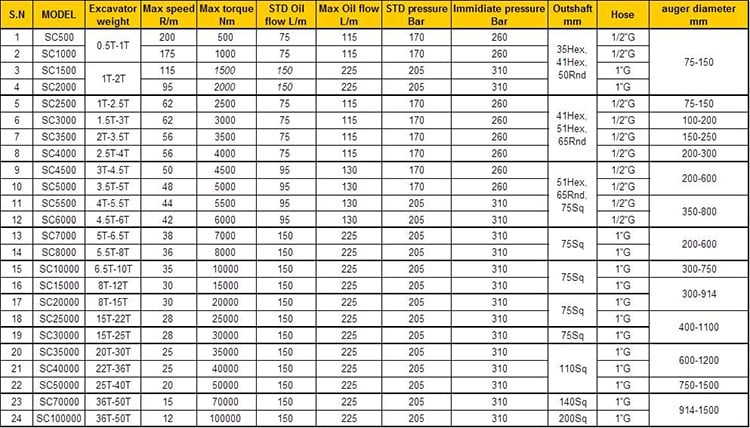

Specification

Auger Drive

1.Forged hoods ears: Deal with the heavy strain of daily use. Contact surface wider and safer.

2.American Motor: Developing the most reliable wear parts.

3.ERICYLIC gearbox: Unique planetary gearbox. Multiplied output torque. Extreme efficiency.

4.NON-dislodgement shaft: Assembled top down locked into earth drill house. Never fall out. Provided a safer environment.

5.18 Month After-sales service for auger drive.

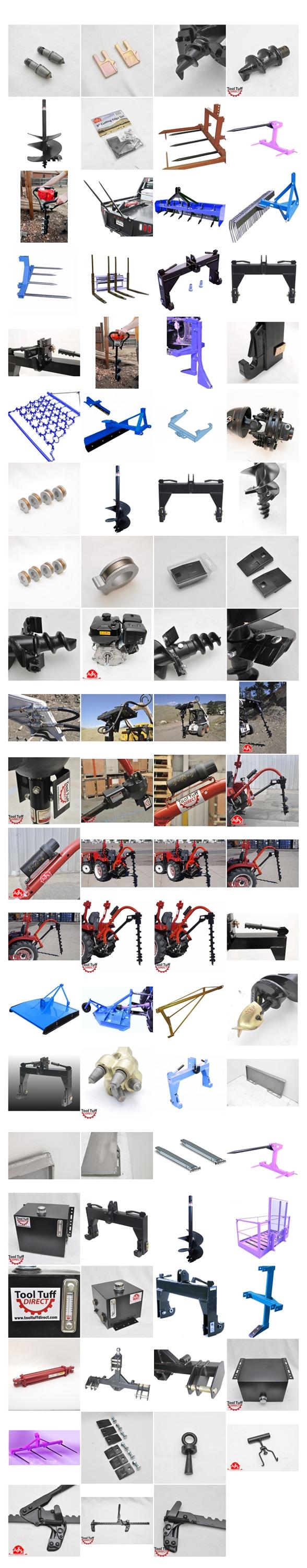

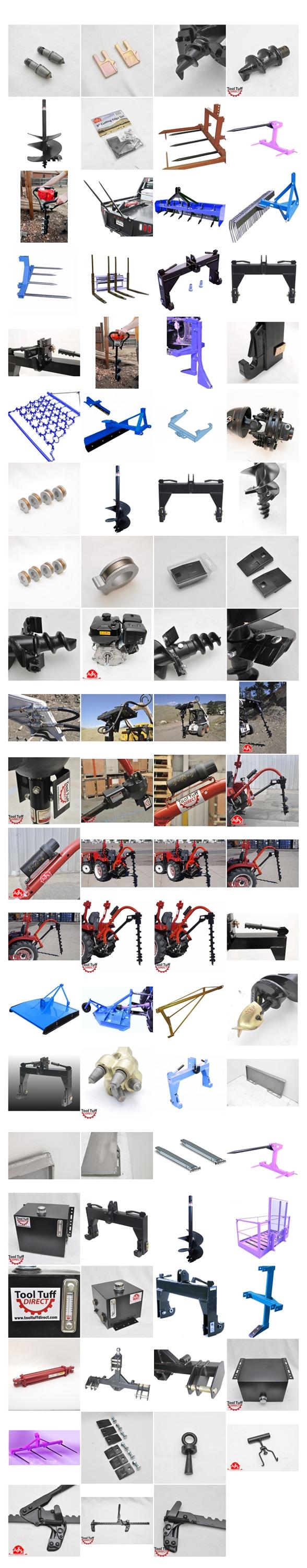

drill dirt auger bit Soil Auger Drill Bit Earth Soil Auger Drill Machine

How to choose the most suitable type?

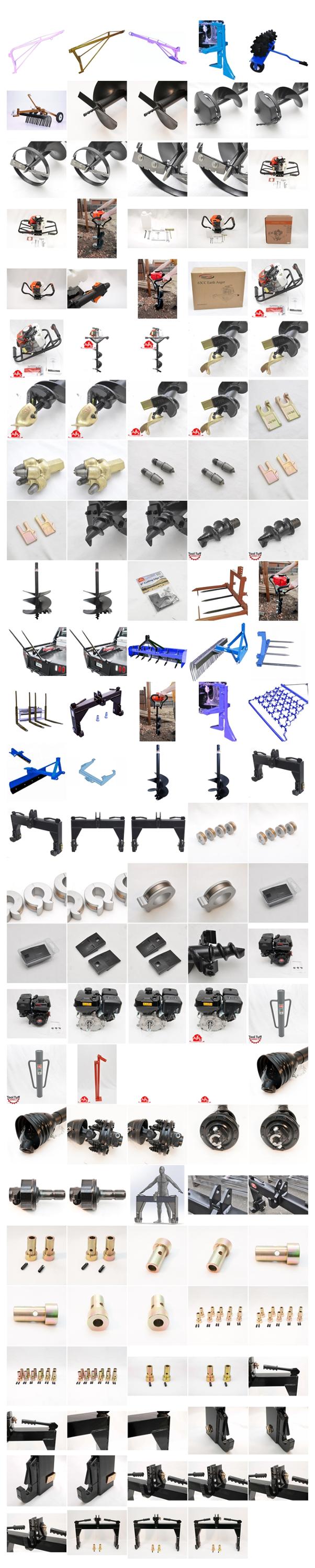

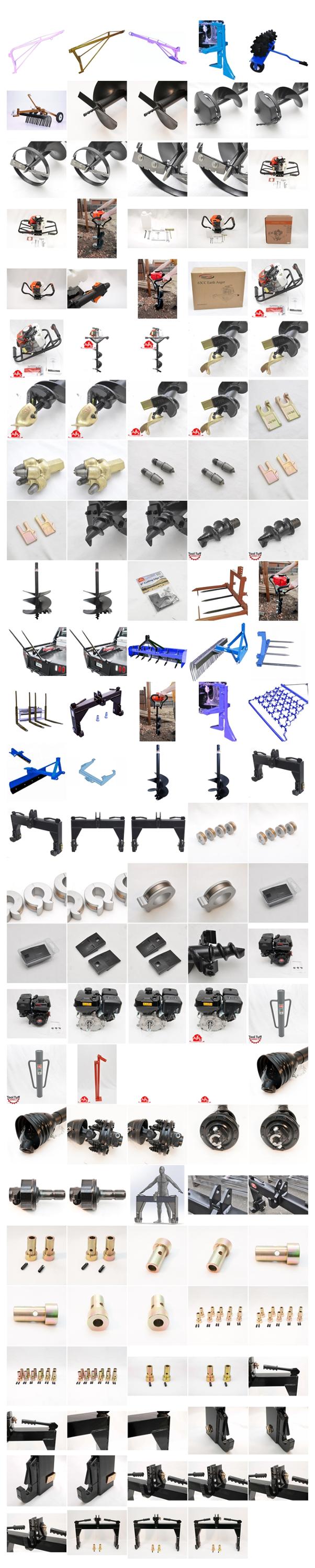

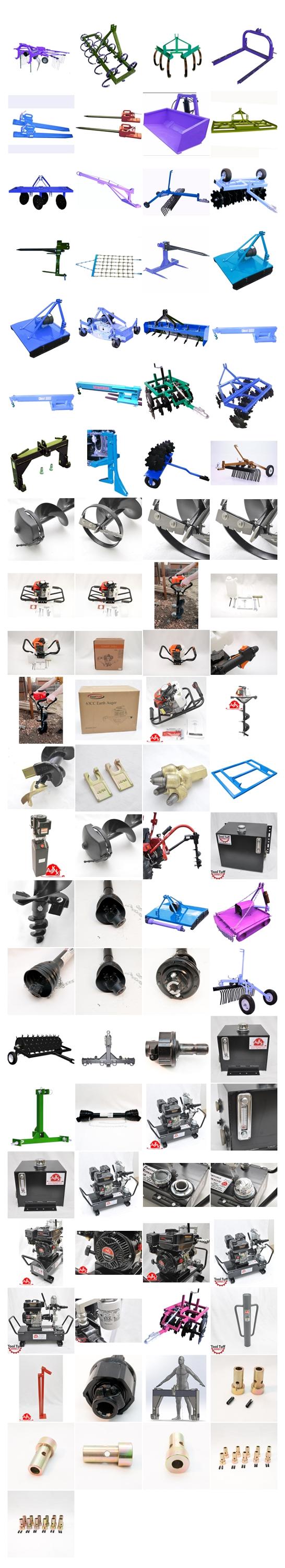

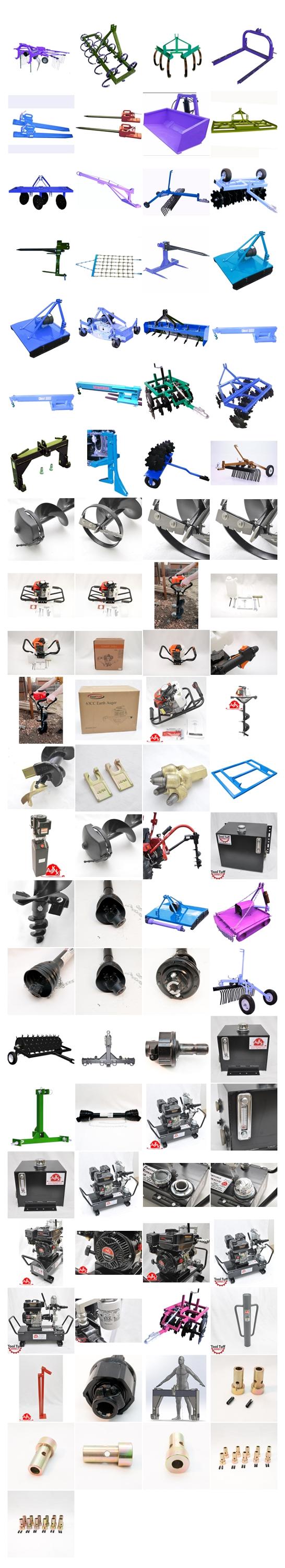

Related spare parts

Our auger teeth have patented unique design.Different teeth for different earth condition.

With those, I believe it is no problem to dig your dream hole.

more auger photos

Factory & Packaging

FAQ

Q: HOW CAN I CHOOSE THE SUITABLE EARTH DRILL?

A:PLEASE REFER TO BELOW QUESTIONS:

- 1. Brand and model of Excavator/Backhoe/Skid Steer loader?

- 2. Diameter of hole to be drilled?

- 3. Depth of hole to be drilled?

- 4. Ground type to be drilled?

Once you have answered the above you can easily make the correct choice.

Q: DO I NEED TO PURCHASE SPARE PARTS WHEN ORDERING AN EARTH DRILL?

A: It is not necessary to purchase spare parts for the Planetary Drive as this is a sealed unit, however it is important to follow the service schedule as outlined in the operators manual. It is advisable to purchase spare wearing parts (teeth and Pilots).

Q: CAN THE EARTH DRILL FIT A VARIETY OF MACHINES?

A: Yes, as long as the carrier’s specifications agree with the parameters of the Earth Drill as outlined in our catalogue.

Q: HOW DO I FIT THE EARTH DRILL TO MY MACHINE?

A: There are four types of mounting linkage available;

- Double Pin Hitch: to be used with excavators fitted with quick couplers.

- Double Pin Cradle hitch: also to be used with excavators fitted with quick hitch, in addition the Cradle hitch can be used to stabilise the Earth Drill whilst travelling around the site and also to aid in the clearing of spoil from the auger.

Q: WHAT CAN I DRILL?

A: There are 3 types of cutting teeth available,

1.Earth and Clay Teeth: Suitable for drilling earth and clay.

2.Tungsten Teeth: Suitable for drilling hard and abrasive ground.

3.Rock Teeth: Suitable for drilling soft, fractured, rock.

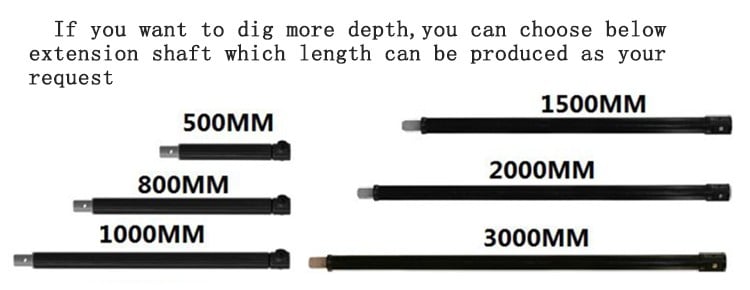

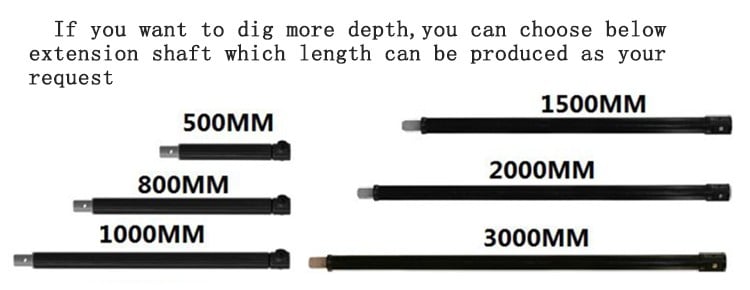

Q: HOW DEEP CAN I DRILL?

A: There are extensions available for every Earth Drill however maximum drilling depth depend on the following conditions;

- Diameter of hole to be drilled

- Depth of hole to be drilled

- Type of parent machine to be used

- Ground type to be drilled

Other attachments